Description

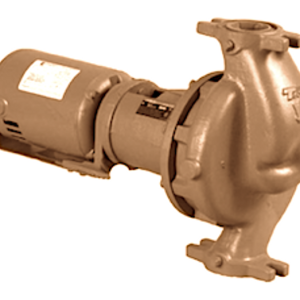

For applications demanding maximum corrosion resistance and material purity, the Armstrong 174034MF-043 H-32 AB Bronze Centrifugal Pump delivers exceptional performance and durability. This versatile pump features all-bronze construction, making it the definitive choice for domestic water systems, marine applications, coastal installations, and chemical services where standard cast iron pumps would rapidly deteriorate. Its robust centrifugal design ensures reliable fluid handling in the most challenging environments where material compatibility is critical.

The pump combines Armstrong’s proven hydraulic engineering with premium bronze construction throughout the liquid end, providing superior protection against rust, corrosion, and galvanic degradation. The bronze alloy offers excellent resistance to saltwater, aggressive water chemistries, and various chemical solutions, while maintaining compliance with potable water standards. With its efficient impeller design and optimized volute configuration, the H-32 AB delivers consistent performance while operating quietly and efficiently. For help with material selection, read our guide on [Selecting Pump Materials for Corrosive Fluid Handling].

As part of Armstrong’s respected H-32 series, this bronze pump continues a tradition of quality that mechanical engineers and facility managers trust for critical applications. Whether moving domestic water in a commercial building, handling seawater in a marine environment, or circulating chemical solutions in an industrial process, the 174034MF-043 provides the material integrity and reliable performance needed for long-term system operation. Learn about its advantages in our article [The Benefits of Bronze Construction in Fluid Handling Systems].

Technical Specifications

| Specification | Details |

|---|---|

| Model | Armstrong H-32 AB (174034MF-043) |

| Construction | All-Bronze Liquid End |

| Connection Size | 1-1/4″ FIPT x 1-1/4″ FIPT |

| Impeller Material | Bronze |

| Housing Material | Bronze |

| Shaft Material | Stainless Steel |

| Seal Type | Mechanical Seal |

| Max Head | 40 ft (12.2 m) |

| Max Flow | 70 US gpm (265 L/min) |

| Max Operating Pressure | 125 psi (8.6 bar) |

| Max Fluid Temperature | 250°F (121°C) |

| Motor Compatibility | Various NEMA Frame Motors |

Comparison Table: Armstrong H-32 AB vs. Alternative Materials

| Feature | Armstrong H-32 AB (Bronze) | Cast Iron Pump | Stainless Steel Pump |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Superior |

| Material Cost | Moderate | Low | High |

| Chemical Compatibility | Good (Broad Range) | Limited | Excellent |

| Potable Water Approved | Yes | No | Yes |

| Marine Application | Excellent | Not Recommended | Excellent |

| Thermal Conductivity | Excellent | Good | Poor |

Frequently Asked Questions (FAQs)

Q1: What applications is this bronze centrifugal pump best suited for?

The H-32 AB is ideal for domestic water systems, marine and boat applications, coastal building systems, chemical transfer, swimming pool systems, and any application where iron contamination cannot be tolerated or where the fluid chemistry would corrode standard materials.

Q2: Is this pump suitable for potable water applications?

Yes, the all-bronze construction makes the H-32 AB suitable for domestic hot and cold water systems. The materials are safe for contact with potable water, unlike cast iron pumps which are restricted to closed-loop applications only.

Q3: What type of motor is required for this pump?

This is a pump-only unit that requires a separate NEMA frame motor. The specific motor horsepower and speed will depend on your application requirements. We offer complete [Armstrong Pump and Motor Packages] with properly matched components for your specific needs.

Q4: How does bronze compare to stainless steel for corrosive applications?

Bronze offers excellent corrosion resistance for most water applications, particularly in marine environments, at a more moderate cost than stainless steel. While 316 stainless provides broader chemical resistance, bronze is often the preferred traditional material for domestic water and seawater applications due to its proven longevity and reliability.

Q5: What maintenance does this bronze centrifugal pump require?

Routine maintenance includes periodic inspection of the mechanical seal for leaks, motor bearing lubrication (if specified), and ensuring the pump operates within its performance curve. The robust bronze construction significantly reduces corrosion-related maintenance concerns.

Pros and Cons

| Pros | Cons |

|---|---|

| Excellent Corrosion Resistance for long service life | Higher Initial Cost than cast iron pumps |

| Potable Water Approved for domestic water systems | Requires Separate Motor Purchase |

| Superior Material Purity – no iron contamination | Heavier than Composite Materials |

| Excellent Marine Compatibility for saltwater service | Premium Price Point for specialized applications |

| Good Chemical Resistance to many solutions | Limited to Specific Fluid Types |

| Proven Reliability in demanding environments | Motor Not Included – additional component to source |

Conclusion & Ideal Use Cases

The Armstrong 174034MF-043 H-32 AB Bronze Centrifugal Pump represents the optimal solution for applications where material compatibility and corrosion resistance are critical to system longevity and fluid purity. While requiring a higher initial investment than standard pumps, its all-bronze construction ensures reliable performance in environments that would quickly degrade conventional pumps.

This bronze pump is essential for:

-

Domestic Water Systems: Commercial and residential potable water applications

-

Marine Applications: Boat water systems, dock installations, and seawater handling

-

Coastal Buildings: Facilities in salt-air environments requiring corrosion resistance

-

Chemical Services: Handling various chemical solutions within bronze compatibility limits

-

Replacement Applications: Updating older systems where material compatibility is crucial

For applications requiring broader chemical resistance, consider the [Armstrong Stainless Steel Pump Series], while for standard closed-loop heating applications, the [Armstrong Cast Iron Pump Line] offers better value. The H-32 AB fills the critical niche for applications requiring the proven corrosion resistance of bronze construction.

Contact our pump specialists today to discuss your specific application requirements and complete your pump package with a properly matched motor and drive components.