Description

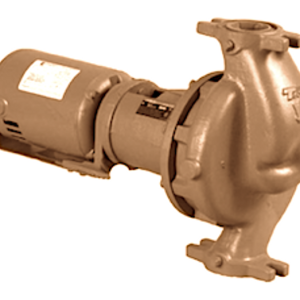

Taco 1915D1E1 Stainless Steel Centrifugal Pump | Ultimate Product Guide

The Taco 1915D1E1 is a robust, close-coupled centrifugal pump designed for demanding commercial, industrial, and chemical applications where corrosion resistance is paramount. Constructed with stainless steel wetted parts, this pump is engineered to handle aggressive fluids that would rapidly degrade standard cast iron pumps. Powered by a versatile 1/2 HP, 3-phase motor with 208-230/460V capability, it offers installation flexibility for various industrial power supplies.

As part of the durable Taco 1900 Series, this model features a simple yet highly effective design with a back pullout capability, allowing for easier maintenance of the seal and rotating assembly without disturbing the motor or piping. Ideal for chemical transfer, food processing, water treatment, and other harsh environments, the Taco 1915D1E1 delivers reliable performance where other pumps would fail.

Detailed Technical Specifications

| Feature | Specification |

|---|---|

| Manufacturer | Taco Comfort Solutions |

| Series | 1900 Series |

| Model | 1915D1E1 |

| Pump Type | Close-Coupled, Centrifugal |

| Horsepower (HP) | 1/2 HP |

| Motor Phase | Three Phase |

| Voltage | 208-230/460V (Multi-Tap) |

| Construction | Stainless Steel (Wetted Parts) |

| Connection Type | Flanged |

| Connection Size | 1.5″ (Model Specific) |

| Seal Type | Mechanical Seal (Material Varies) |

Key Features & Benefits

-

Stainless Steel Construction: Provides superior corrosion resistance for handling acids, caustics, solvents, and other aggressive fluids.

-

Back Pullout Design: Enables service of the seal, impeller, and bearing frame without disconnecting the pump from the piping.

-

Three-Phase Power: Offers higher efficiency, simpler design, and greater torque for industrial settings.

-

Multi-Voltage Motor: Can be wired for 208-230V or 460V operation, providing flexibility for different facility power supplies.

-

Flanged Connections: Provide a strong, leak-free connection suitable for higher-pressure industrial piping.

-

Reliable & Simple: A time-tested, mechanically simple design known for durability and ease of maintenance.

Taco 1915D1E1 vs. Standard Cast Iron Pumps: Comparison Table

This table highlights the critical advantage of stainless steel construction.

| Feature | Taco 1915D1E1 (Stainless Steel) | Standard Cast Iron Pump |

|---|---|---|

| Construction | Stainless Steel (Corrosion Resistant) | Cast Iron (Prone to Rust) |

| Primary Use | Chemical, Food, Process, Harsh Environments | Clean Water, Closed-Loop HVAC |

| Fluid Compatibility | Excellent for Aggressive/Caustic Fluids | Limited to Non-Corrosive Fluids |

| Lifespan in Harsh Apps | Long | Very Short |

| Initial Cost | Higher | Lower |

| Maintenance | Back Pullout for Easier Service | Varies |

| Motor Type | 3-Phase (Industrial) | Often Single Phase |

Frequently Asked Questions (FAQ)

Q1: What specific type of stainless steel is used?

A: Taco typically uses 316 stainless steel for its superior corrosion resistance, especially against chlorides and acids. However, for the exact specification of the 1915D1E1 model (e.g., 304 vs. 316 SS), you should consult the official Taco specifications or product data sheet.

Q2: Is this pump suitable for potable water?

A: While stainless steel is generally excellent for potable water, the pump’s suitability depends on the specific grades of stainless and seals used. If needed for drinking water, you must confirm that the pump meets NSF/ANSI 61 or other relevant potable water standards. It is likely designed for industrial process fluids.

Q3: How do I wire the motor for different voltages?

A: The motor is multi-voltage. The connection diagram on the motor’s nameplate will provide specific instructions for wiring it for either 208-230V or 460V operation. It is absolutely critical to ensure the power supply matches the wiring configuration. This should be performed by a qualified electrician.

Q4: What does “back pullout” capability mean?

A: This is a major service advantage. It allows a technician to unbolt the entire rotating assembly (impeller, shaft, bearings, seal) and pull it straight back from the volute (pump body) for service. The motor stays aligned on its base, and the piping connections remain undisturbed, saving significant labor time.

Q5: What applications is this pump designed for?

A: This pump is built for harsh and industrial duties, including:

-

Chemical Transfer and Metering

-

Food and Beverage Processing

-

Industrial Washdown Systems

-

Water Treatment and Chemical Feed

-

Transfer of Solvents, Acids, and Caustics

-

Process Lines in Manufacturing

Q6: What kind of mechanical seal does it use?

A: Industrial pumps like this often come with a standard seal suitable for water. For chemical service, the seal material is critical. It may be offered with various seal options (e.g., Viton, EPDM, Silicon Carbide faces) to ensure compatibility with the specific fluid being pumped. You must specify the fluid when ordering to get the correct seal.

Pros and Cons

Pros:

-

Excellent Corrosion Resistance: Stainless steel construction allows it to handle fluids that destroy standard pumps.

-

Industrial Duty: The 3-phase motor is designed for continuous operation in demanding environments.

-

Easy Maintenance: The back pullout design drastically reduces downtime for seal and impeller service.

-

Voltage Flexibility: The multi-tap motor can adapt to common industrial voltages.

-

Reliable Brand: Taco is a trusted name in commercial and industrial pumping.

-

Flanged Connections: Ideal for industrial pipe systems where a robust connection is required.

Cons:

-

Higher Initial Cost: Stainless steel construction and industrial features come at a premium price.

-

Requires 3-Phase Power: Limits its use to facilities with 3-phase electrical service; not suitable for residential or typical small commercial sites.

-

Not a General-Purpose Pump: Overkill and unnecessarily expensive for simple water circulation in a closed, clean loop.

-

Seal Material Dependency: Performance with aggressive chemicals is highly dependent on selecting the correct mechanical seal material, which may be a separate consideration.

Conclusion & Best Applications

The Taco 1915D1E1 is a specialized workhorse designed for one primary purpose: reliably moving corrosive and aggressive fluids in an industrial setting. It is the ideal choice for plant engineers and maintenance managers who need durability and chemical resistance.

You should choose this pump if:

-

You are pumping acids, caustics, solvents, or other corrosive chemicals.

-

Your application is in food processing, chemical manufacturing, or water treatment.

-

You have a 3-phase power supply available.

-

Ease of maintenance and minimizing downtime are critical concerns.

For challenging pumping applications where standard pumps fail, the Taco 1915D1E1 provides a reliable and effective solution.

Disclaimer: Professional installation is required. Ensure the wetted materials (stainless steel grade, seal materials) are compatible with the specific fluid being pumped, including its concentration and temperature. The pump must be wired by a qualified electrician to match the available power supply. Always confirm the specific performance curve (GPM and Head) matches your system requirements.